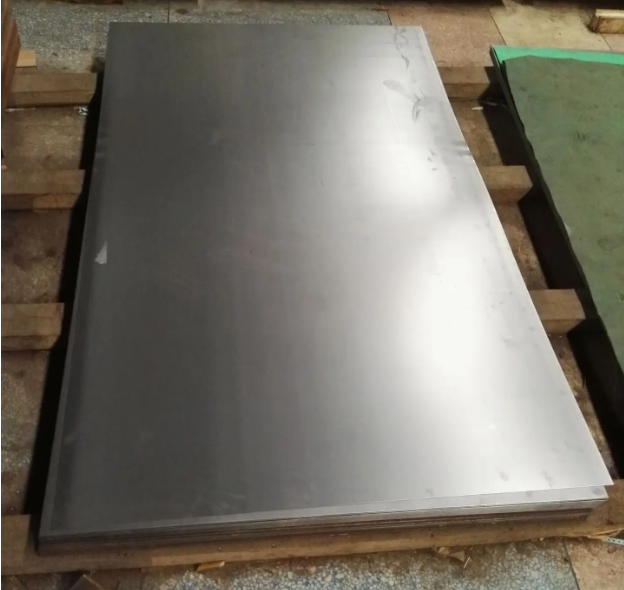

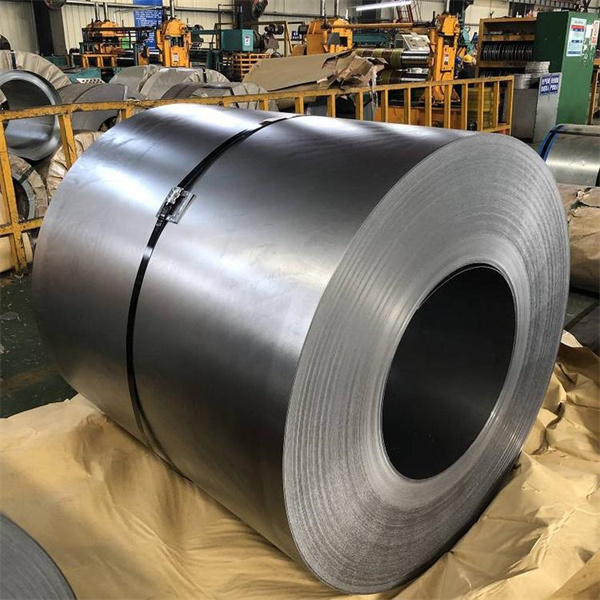

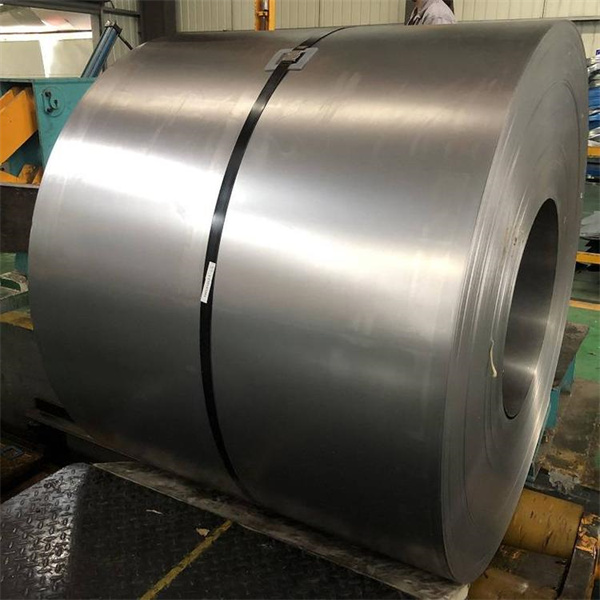

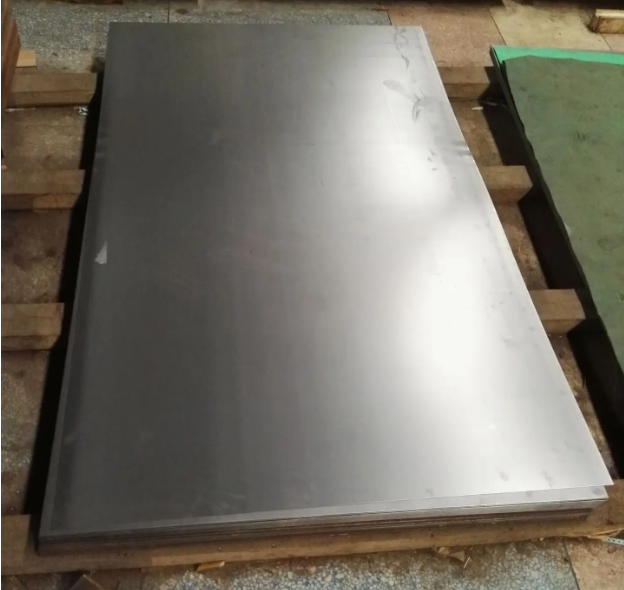

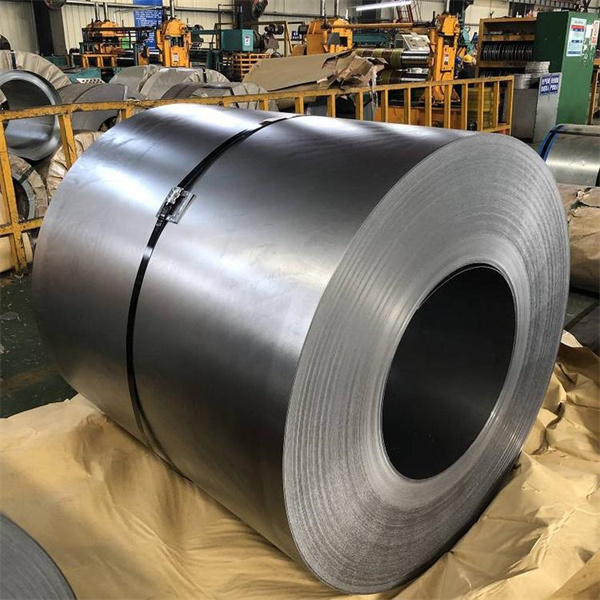

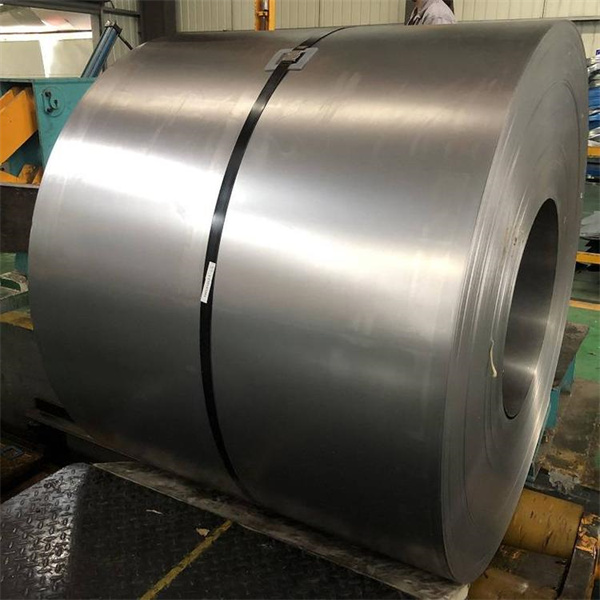

Cold-rolled strips are widely used, such as automobile manufacturing, electrical products, rolling stock, aviation, precision instruments, canned food, etc. Cold-rolled sheet is the abbreviation of ordinary carbon structural steel cold-rolled sheet, also known as cold-rolled sheet, commonly known as cold-rolled sheet, and sometimes mistakenly written as cold-rolled sheet. The cold plate is a hot-rolled steel strip of ordinary carbon structural steel, which is further cold-rolled into a steel plate with a thickness of less than 4mm. Due to rolling at room temperature, no scale is produced, therefore, the cold plate has good surface quality and high dimensional accuracy, coupled with annealing treatment, its mechanical properties and process properties are better than hot-rolled steel sheets, in many fields, especially In the field of home appliance manufacturing, it has gradually replaced hot-rolled sheet steel.