Kungang steel pipe for new

Kungang steel pipe products are bright stars, such as pipeline pipes all over the world, oil casing pipes for land and sea drilling, structural pipes supporting the terminal building of the Capital International Airport, and high-pressure boiler pipes used in supercritical boilers, etc.

The seamless steel pipe for gas cylinder is one of the "new stars" identified this time. If it is said that which product is more difficult to roll in the seamless steel pipe, the seamless steel pipe for gas cylinder has always been among the best. According to the senior engineer of Kungang Steel Pipe Co., Ltd., seamless steel pipes for gas cylinders are used as raw materials for manufacturing high-pressure gas cylinders and accumulators. For continuous rolling mills, seamless pipe specifications are extremely thin-walled products, and the control is more difficult.

Recently, the seamless steel pipes for gas cylinders sent by Kungang Steel Tube Co., Ltd. to Central Asia have been successfully delivered to users. The maximum diameter-to-wall ratio of the outer diameter produced in this contract exceeds 46, which is an extremely thin-walled tube. Although the production is very difficult, the surface quality and dimensional accuracy are strictly controlled according to the needs of users. In recent years, the 180MPM continuous rolling tube unit and 159, 460PQF continuous tube rolling unit equipped by Kungang Steel Tube Co., Ltd. have formed a stable and mature gas cylinder tube production process through systematic optimization and upgrading. Not only the product specifications and materials are comprehensive, but also the product surface quality is good and the geometrical precision is high. It is favored by leading companies in the gas cylinder industry such as Beijing Tianhai, and is also exported to South Korea and other countries along the "Belt and Road" countries. Gas cylinder manufacturing enterprises.

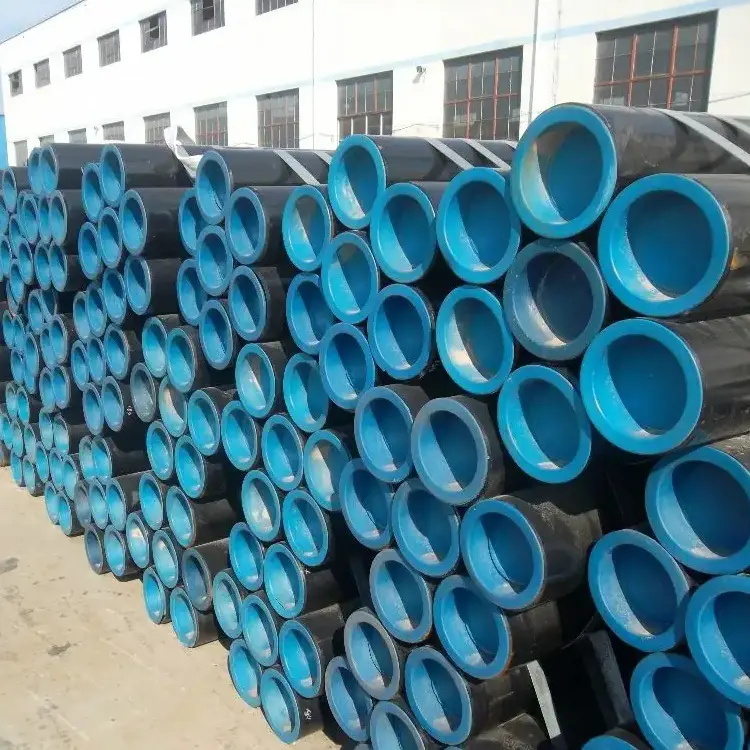

Kungang seamless steel pipes are widely used in industries such as fluid transportation, oil exploration and development, high-pressure boiler units, and building structure pipes.

The load-bearing axle is one of the three core power components of the truck, which has an important impact on the stability and load-bearing performance of the vehicle. The reporter learned that traditional load-bearing axles are produced by steel plate shearing, stamping, bending, welding and other processes. The process is complicated and the quality of the welds is difficult to guarantee, and the safety factor is low. The load-bearing axles produced by Kungang axle tubes have high safety factor and long service life, and are trusted and praised by users. We will also rely on the high recognition of the market and strong research and development capabilities to continue to develop more axles that meet the needs of users. Seam steel pipe.

my country's steel industry has experienced a development process from scratch, from small to large, from weak to strong, and gradually built the largest and most complete steel industry system in the global industrial chain, and its products are also accelerating towards high-end products. For iron and steel enterprises, homogeneous competition will also spread to high-end products in this process, and the development path of variety steel will be towards higher quality, higher precision, lower manufacturing cost and better sales service. Kungang Steel Pipe Co., Ltd. is constantly accelerating the upgrading of product structure and improving the supply capacity of mid-to-high-end products. At the same time, fully based on the already formed product structure advantages, it has made great efforts in quality, precision, manufacturing costs and other aspects. On the one hand, it has increased the added value of products. On the other hand, it has continuously consolidated the market share of Kungang's seamless steel pipe products.

Post time: Aug-18-2023