Do you know about A36 American standard steel plates?

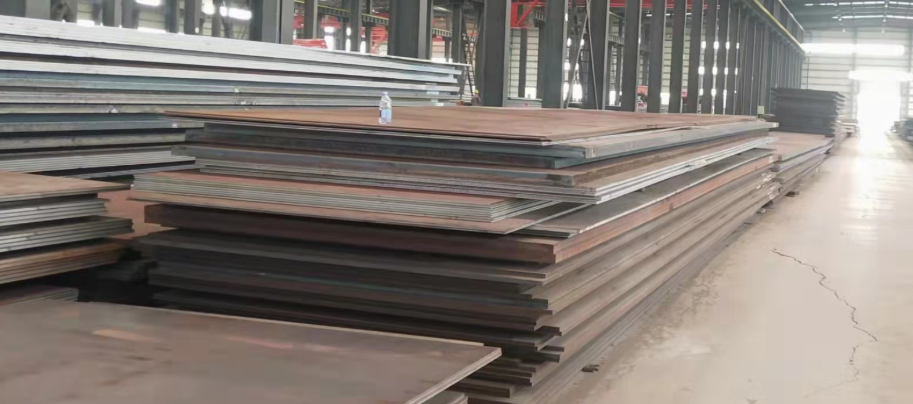

A36 American standard steel plate is a common structural steel plate that meets the American ASTM A36 standard and has excellent weldability, plasticity, and corrosion resistance. From the perspective of mechanical properties, A36 American standard steel plate has high strength and toughness, which can meet the requirements of most structural engineering applications. It is widely used in fields such as construction, bridges, ships, rail transit, and machinery manufacturing. In addition, A36 American standard steel plate also has good compressive performance, which can withstand certain loads and pressures, ensuring the stability and safety of the structure. In terms of chemical composition, A36 American standard steel plate is mainly composed of elements such as carbon, manganese, sulfur, and phosphorus. The content determines the hardness and strength of the steel plate, while a higher content can improve the plasticity and toughness of the steel plate. The content of sulfur and phosphorus has a certain impact on the welding performance.

In addition, A36 American standard steel plate has some other characteristics. Firstly, its quality is stable and the production process is strict, ensuring that the quality of each steel plate meets the standard requirements. Secondly, the surface of A36 American standard steel plate is smooth and flat, without obvious defects, making installation and use more convenient. In addition, A36 American standard steel plate is a recyclable and environmentally friendly material that meets the requirements of sustainable development. In short, A36 American standard steel plate is a structural steel plate with stable performance and reliable quality, widely used in various engineering projects.

The manufacturing process of ASTM A36 steel plate mainly includes processes such as continuous casting, hot rolling, cold rolling, annealing, etc. Firstly, the raw materials are melted into steel billets at high temperatures, and then continuously cast to obtain steel ingots. Next, the steel ingots are hot-rolled and cold-rolled to obtain the required specifications of steel plates. Finally, the steel plate is annealed to eliminate internal stress and improve its mechanical properties and stability. In addition, in order to improve the surface quality and accuracy of the steel plate, it is necessary to carry out processes such as leveling, straightening, and precision cutting.

Shandong Kungang Metal Technology Co., Ltd. is a comprehensive enterprise that integrates steel trading, comprehensive logistics, and agency sales. In addition to selling American standards, there are also special specifications of steel plates such as European standards, German standards, and Japanese standards. Welcome to inquire and hope that we can work together to create brilliance!

Post time: Dec-08-2023