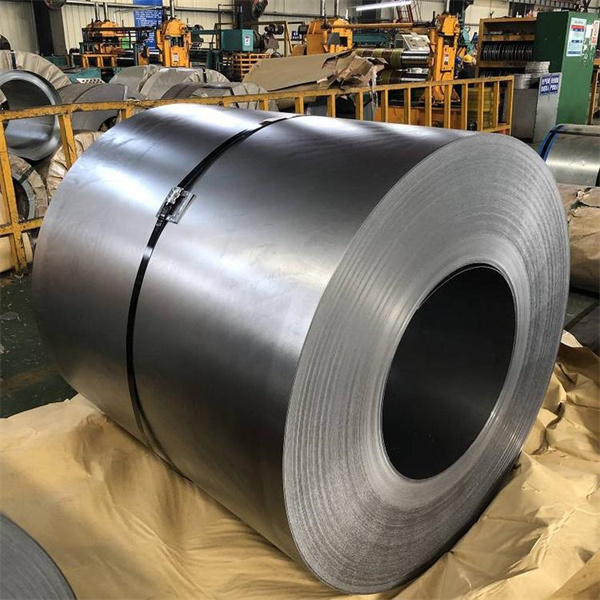

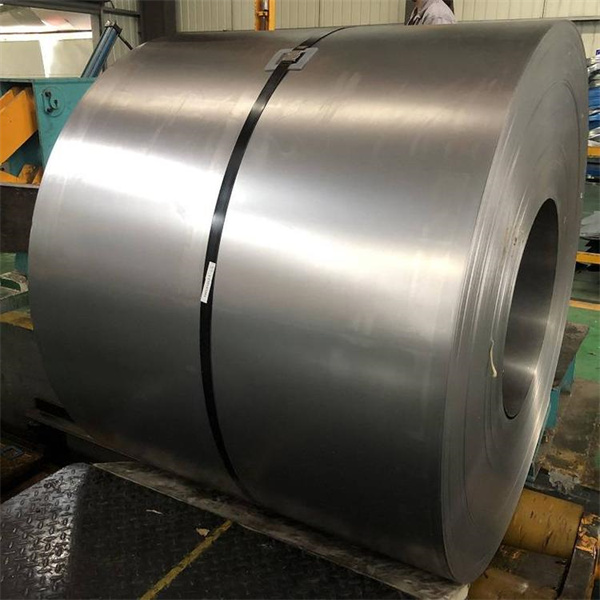

The surface Rockwell hardness of annealed plain carbon steel is generally 55+-3, and the hardness of unannealed hard-rolled cold-rolled strip steel is above 80. Cold-rolled strip and sheet generally have a thickness of 0.1-3mm and a width of 100-2000mm; both are made of hot-rolled strip or steel plate. .

CRS is the abbreviation of English cool rolled steel, that is, cold rolled steel. It refers to a rolling process of steel. For example, q235 ordinary carbon steel plate can be cold rolled, and 10# steel plate can also be cold rolled. Its hardness can be on the corresponding standard according to the steel grade used. .

What is the grade of cold-rolled sheet harder than spcc? .

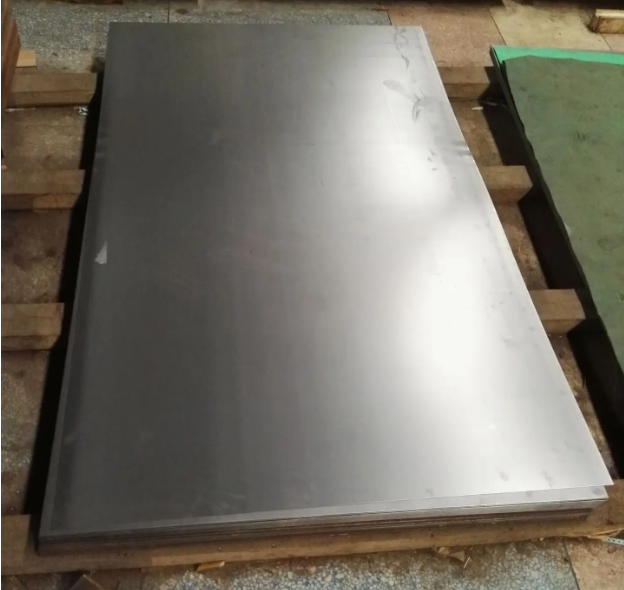

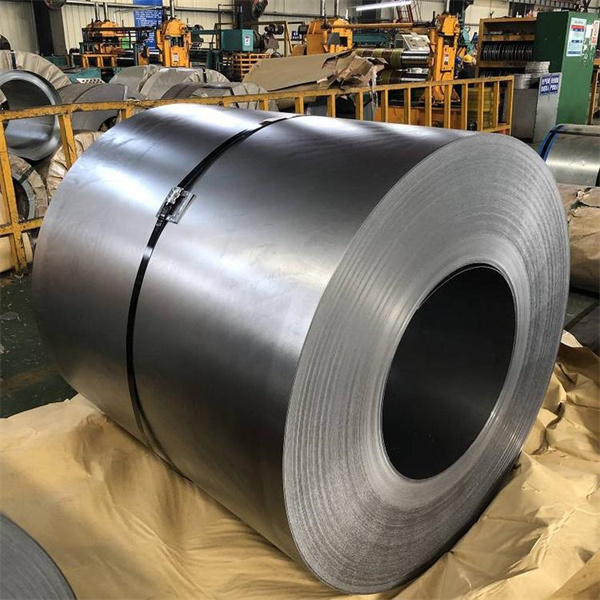

Cold-rolled sheet is the abbreviation of ordinary carbon structural steel cold-rolled sheet, also known as cold-rolled sheet, commonly known as cold-rolled sheet, and sometimes mistakenly written as cold-rolled sheet. The cold plate is made of ordinary carbon structural steel hot-rolled steel strip, which is further cold-rolled into steel with a thickness of less than 4mm. .

The cold-rolled sheet is divided into: 1/8 hard, 1/4 hard, 1/2 hard and full hard state. There are generally two main units of hardness value: HRB (Rockwell) HV (Vickers) as follows: Quality distinguishing symbol HRB (Rockwell) HV (Vickers) 1/8 hard. .

Pickling plate is a hot-rolled plate that is subjected to a process such as dephosphorization (removal of rust, residues, etc., produced during hot-rolling) and other processes to pickle the surface to obtain a steel plate with better performance than hot-rolled surface. It can be seen from its manufacturing process that its hardness is hot rolled with the same grade. .

There is basically no difference in surface hardness between cold-rolled and galvanized. Because the galvanized surface is only plated with a layer of zinc from a few microns to about 20 microns on the substrate. The substrates are generally cold-rolled and hot-rolled. The hardness mainly depends on the grade of the material, and the grades vary. .

Take DC01, DC03 as an example. DC01 upper limit of yield strength 280 DC03 upper limit of yield strength 240 , dc06+ze, they correspond to the cold-rolled sheet, the number represents the stamping grade, and the larger the number is.

Cold-rolled sheet is made of hot-rolled coil as raw material, rolled at room temperature below the recrystallization temperature, and its hardness is about 150HV. The shearing machine blades are generally made of tool steel, with a hardness of HRC55~58°, which can cut most of them.