Translation results

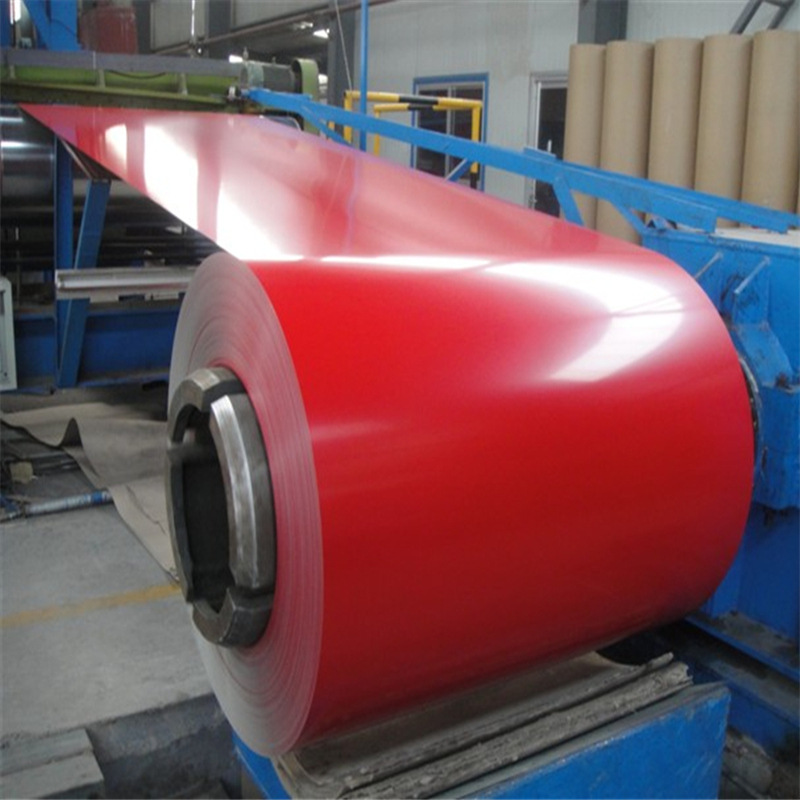

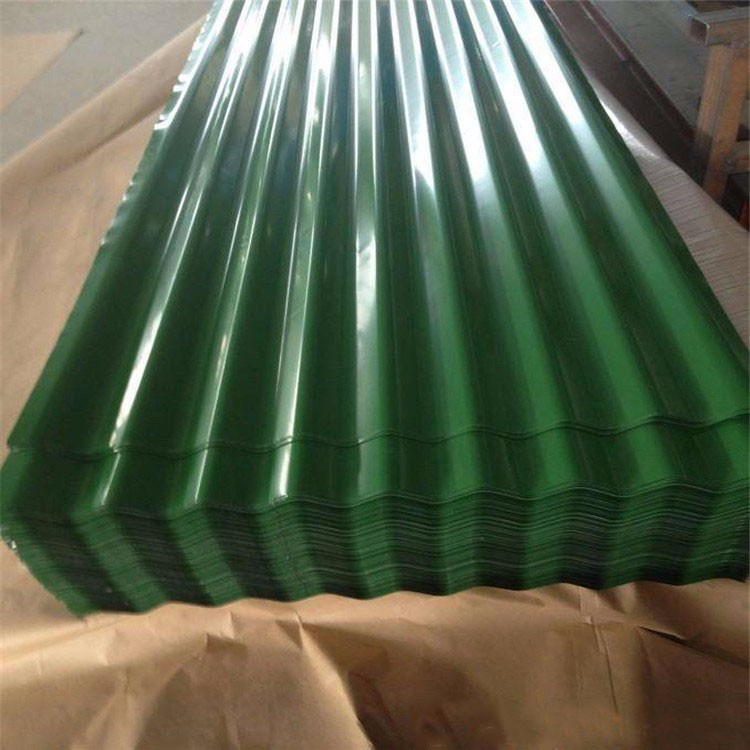

The paint film coating of the embossed color coating roll is divided into four kinds: ① polyester coating (PE) color coating; ② high durability coating (HDP) color coating; ③ silicon modified coating (SMP) color coating board; ④ fluorocarbon coating (PVDF) color-coated board;

1. Ester coating (PE) color coated board

PE polyester color-coated sheet has good adhesion, rich color, wide range in formability and outdoor durability, medium chemical resistance, and low cost. The advantages of PE polyester color-coated board are mainly cost-effective, and it is recommended to use PE polyester color-coated board in a relatively friendly environment;

2. High weather resistance coating (HDP) color coated board;

HDP high weathering color coated board has excellent color retention and anti-ultraviolet performance, excellent outdoor durability and chalk resistance, good paint film coating adhesion, rich colors, and excellent cost performance. The most suitable environment for high-weather-resistant HDP pressure-type color-coated rolls is harsh weather environments, such as plateaus and other areas with strong ultraviolet rays, we will recommend the use of HDP high-weather-resistant pressure-type color-coated rolls;

3. Silicon modified coating (SMP) color coated board;

The hardness, abrasion resistance and heat resistance of the SMP silicone polyester color-coated plate coating film are good; as well as good external durability and chalk resistance, gloss retention, general flexibility, and moderate cost. The most suitable environment for SMP silicon-modified polyester embossed color-coated coils is high-temperature workshops. For example, steel mills and other environments with high indoor temperatures are generally recommended to use SMP silicon-modified polyester embossed color-coated coils;

4. Fluorocarbon coating (PVDF) color coated board;

PVDF Fluorocarbon Color Coated Sheet has excellent color retention and UV resistance, excellent outdoor durability and chalk resistance, excellent solvent resistance, good formability, dirt resistance, limited color, and high cost. The high corrosion resistance of PVDF profiled color-coated coils is the choice of PVDF profiled color-coated coils for many workshops with strong corrosive environments, and the often humid sea breeze at the seaside is more corrosive. Generally, PVDF profiled color-coated coils are also selected;